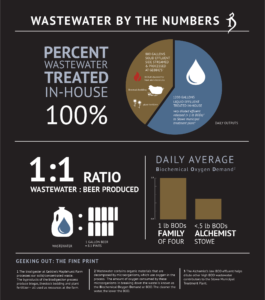

Wastewater is the largest byproduct of the brewing process. We manage this byproduct in 2 ways. First, we side stream (or divert) as much high-strength effluent as possible from our wastewater stream. Second, all of the remaining waste that goes down our drain goes to our state-of-the art wastewater system, before the water is released to our municipal system. By side streaming higher-density wastewater and also pretreating high-strength effluent in-house, we are helping to reduce impact on both the environment and our local wastewater treatment plant.

GALLONS

wastewater pretreated daily

GALLONS

pretreated to date

PERCENT

wastewater pretreated in-house

HIGH STRENGTH EFFLUENT

Biological Oxygen Demand

The effluent waste that brewing produces has high phosphorus content and a high level of Biological Oxygen Demand (BOD). Biological Oxygen Demand represents the amount of oxygen consumed by microorganisms and bacteria that break down organic matter in the water under aerobic conditions (usgs.gov). The higher the demand, the more oxygen is required to break down the waste; the result being lower levels of dissolved oxygen in the water content after decomposition. Lower dissolved oxygen levels in lakes and streams results in stresses on all varieties of aquatic life, leading to algae blooms, dangerous bacterial blooms, and poor water quality.

Municipal Treatment

Many breweries send untreated water, or high-strength effluent, to their local sewer systems via floor drains. This wreaks havoc on our municipal wastewater treatment facilities that are responsible for treating this effluent before releasing it back into local rivers & streams. These publicly-funded, wastewater treatment plants are often outdated and under-sized. Oftentimes, especially after heavy rains or other drastic weather, overstressed treatment plants hit their capacity and release/overflow excess untreated effluent into the nearest body of water. The high BOD levels in this water seriously disrupts the ecosystem and kills aquatic life. Here in Vermont, the health of our rivers, ponds and lakes are at risk. Our biggest body of water, Lake Champlain, is at a critical tipping point – prone to unsafe algae blooms, closed beaches and declining fish populations.

Impact Reduction

We feel it’s our responsibility to side stream what we can and pretreat our wastewater before releasing it into the town sewer system – to lessen the impact on both the municipal treatment plant and on the local environment. That’s why we teamed up with Lake Champlain International for guidance during the construction of our Stowe brewery, to ensure we’re doing our part to protect a fishable, drinkable, and swimmable Lake Champlain for generations to come.

SIDE STREAMING

The process of diverting high-strength wastewater and transporting it for disposal is called side streaming. When we opened our Waterbury based production brewery in 2011, we instituted a vigorous side streaming process – a process we still use today at both our Waterbury and Stowe breweries.

The process of diverting high-strength wastewater and transporting it for disposal is called side streaming. When we opened our Waterbury based production brewery in 2011, we instituted a vigorous side streaming process – a process we still use today at both our Waterbury and Stowe breweries.

The highest strength wastewater is made up of tank wash, hop/yeast residues, spent grain residue (sugars & proteins), and lost process beer. Instead of putting all of this high-strength wastewater down the drain, we collect it in large containers. The containers are picked up daily by our friends at Evergreen Septic Services, who deliver it to either to Gebbie’s Maplehurst Farm in Greensboro or to Purpose Energy in South Burlington, VT for use in their anaerobic bio-digesters, which convert the waste into electricity.

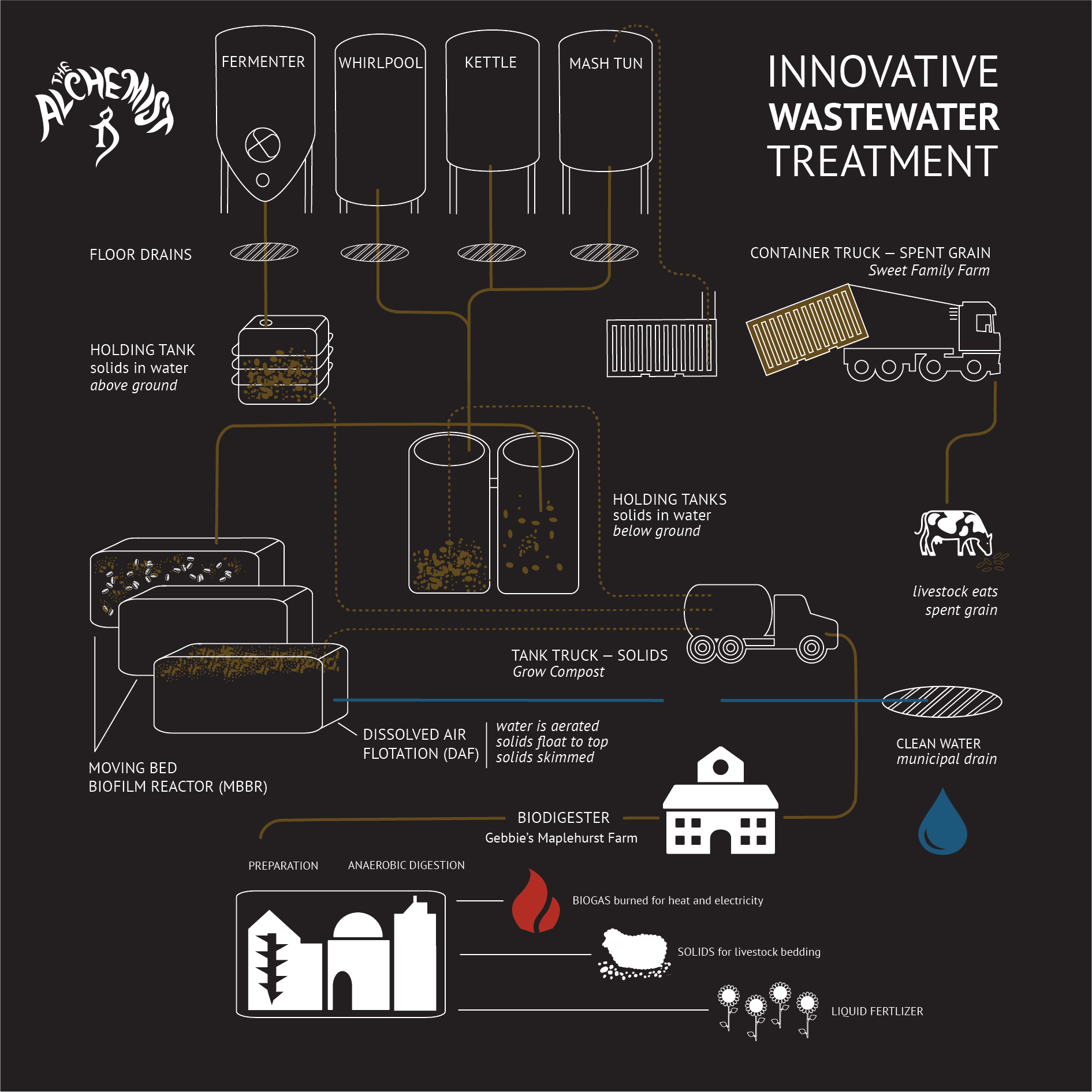

Innovative Water Treatment in Stowe

Our Stowe brewery was built with wastewater pretreatment in mind. After side streaming our high-strength wastes, all remaining brewery wastewater flows into two 5,000 gallon tanks which are buried in front of the brewery. The first tank is a settling tank to allow further solids to drop out. These solids are regularly pumped and delivered to the aforementioned anaerobic bio-digester in Greensboro to be converted to electricity. The water from the settling tank then overflows into the second tank, which has pumps to transfer the waste water into our pretreatment system.

The first step in the pretreatment system is called a Moving Bed Biofilm Reactor (MBBR). The wastewater is mixed with carefully selected aerobic bacteria that consume and break down the leftover high-strength waste, composed mostly of organics and nutrients.

The bacteria multiplies as it consumes leftover solids and eventually flows with the water (fed by gravity) into a Dissolved Air Flotation (DAF) vessel. Here, both a polymer and a coagulant are injected into the waste stream, chemically binding the solids together to make larger particles. Water with high pressure dissolved air is injected into the DAF, which floats the solids to the top layer where they are raked off the surface and sent to the bio-digester with our other high strength wastes.

The final product of the pretreatment system is low-strength water that is discharged to the Town of Stowe’s Wastewater Treatment Facility. We discharge less than 1/10th pound of BOD down our drain each day – far less than the amount of wastewater generated daily by a single family household.