GALLONS

wastewater treated daily

% OF ELECTRICITY

powered by solar

MALT BAGS

recycled weekly

OUR COMMITMENT

The Alchemist is committed to crafting the highest quality beer while focusing on long term sustainability. Brewing is a high impact industry— from the energy we consume to the wastewater we create. It is our responsibility to commit ourselves to using less energy, choosing clean energy and investing in new technologies.

OUR VISION

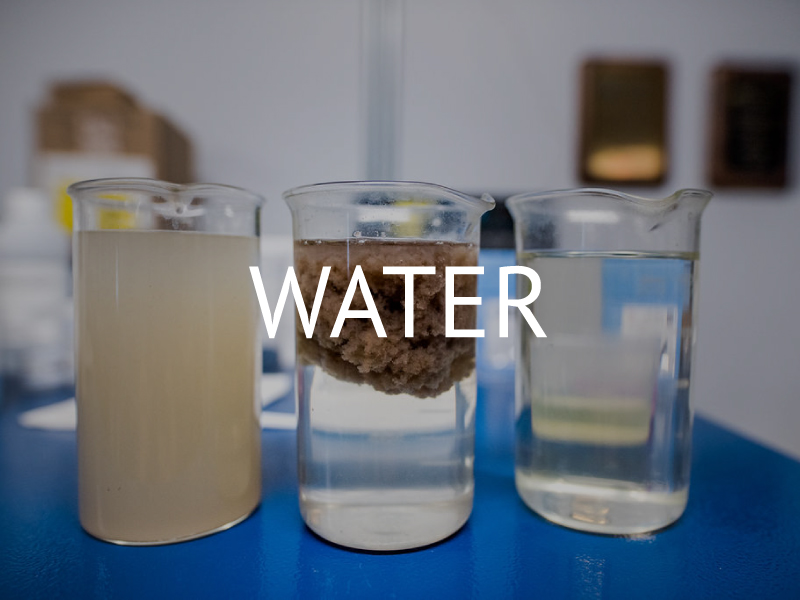

Brewing relies on water, it’s our job to be as efficient as possible to reduce our wastewater impact.

WHAT WE DO

SIDE STREAMING We collect tank wash, hops, yeast, spent grain residue and lost process beer. The wastewater we collect is picked up daily by our friends at Casella Compost, a Vermont composting company. This high strength waste is transported to an anaerobic bio-digester.

WASTEWATER TREATMENT At the Stowe Brewery, after side-streaming our high strength wastes, all remaining brewery wastewater flows into two, 5,000 gallon tanks and undergoes an aerobic bacterial process. The resulting effluent has low BOD (Biological Oxygen Demand) and phosphorus levels and is then discharged into Stowe’s municipal wastewater treatment facility.

SUCCESS TO DATE

Our daily BOD output is less than an average family of four.

OUR VISION

As a BCorp, it is our duty to invest in innovative technologies and create and use as much clean energy as possible.

WHAT WE DO

Over the years, The Alchemist has made investments in renewable energy to power our breweries.

We’ve partnered with All Earth Renewables to power the Waterbury Cannery at 100%. Our excess power is donated to the neighboring Senior Center. In Stowe, we partnered with SunCommon to install solar canopies.

SUCCESS TO DATE

About 60% of our Stowe customer lot is now protected from sun and snow thanks to the solar canopies. Overall, they provide about 178kWh of energy annually, offsetting about 33% of the Stowe brewery’s total energy consumption.

OUR VISION

We aim to be 100% trash free in our facilities and continually work with our suppliers to ensure that the materials that we use get reused and repurposed.

WHAT WE DO

Diverting material waste from the landfill is a huge priority at our breweries. Small steps can make a big difference across our industry and we strive to be a leader in craft beer in getting to zero-waste.

SUCCESS TO DATE

We use about 600-800 bags of grain per week between the two breweries. Our grain bags are our most used material and we have incorporated a system where we are now able to properly recycle all of these bags.